Static in-line mixer made of high-quality stainless steel and rust-proof elements

Body:

Housing: stainless steel 1.4571; Elements: stainless steel 1.4404 or 1.4435

Number of Elements:

12 or 18

Retention of Elements:

Retention ring on downstream and of housing

End Connectors:

Ermeto fitting

Design Pressure:

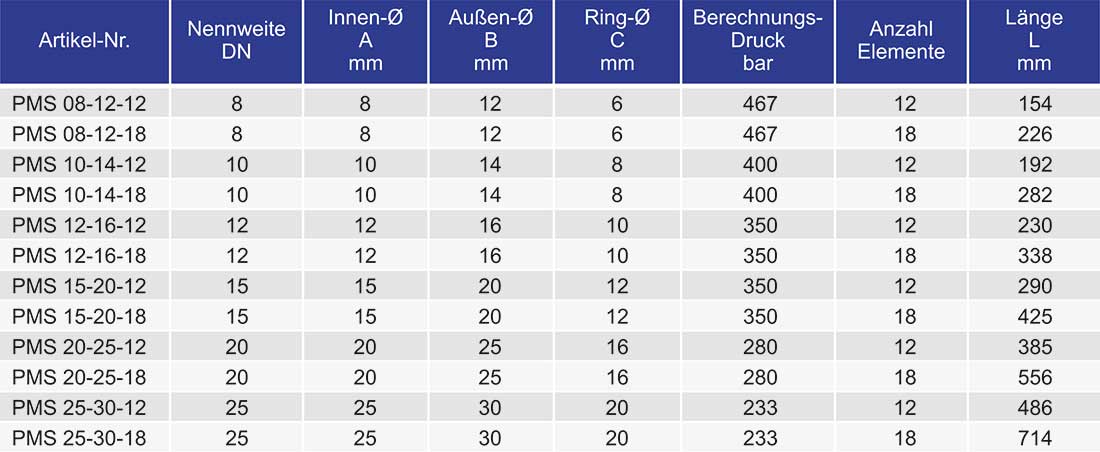

Max. allowable operating pressure (see table below) according to DIN 2413, scope of application I, permanent elongation limit 1% at 20°C, safety factor 1.7

Tolerances:

O.D. and wall: According to DIN 2391, page 1; Length +/- 1mm.

STATICS IN-LINE MIXER Unities with fixed elements of the class PMS-1 are particularly suitable and have been especially developed for the merging of two-component synthetic resin systems with filler material as well as with silicone foam or silicone compounds, which do not allow measures of conventional cleaning.

All mixers of this class are equipped with extractable groups of elements. The retention of the groups of elements is guaranteed by the bolt connection by means of a retention-ring. In order to avoid a tightening of the internal diameter of the conduit and hence a trapping of the elements screw connections should be moderately tightened.

In case that all the entire group of components should be removed in order to be subjected to cleaning it might be necessary to put the mixer into a solvent dip after the pre-cleaning. All components should be then carefully removed with an arbor form the body. We disadvise to pull the elements out or to knock them out with hard hits.