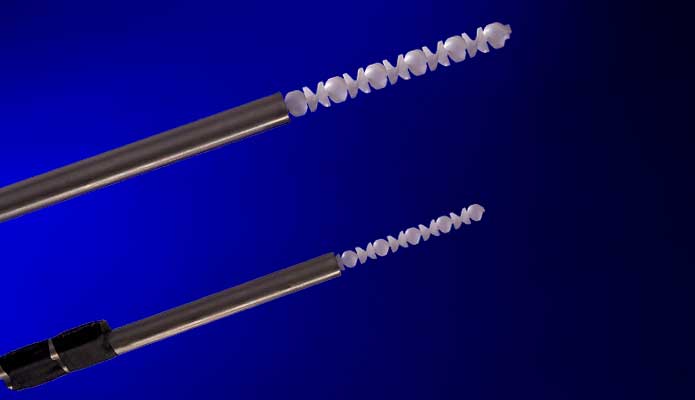

Gehäuse aus Edelstahl, Element aus weißem Teflon

Body:

Housing: zinc-plated carbon steel St 35 (stainless steel available on request)

Elements:

fibreglass reinforced engineering plastic (PBT)

Number of Elements:

24 or 36

Retention of Elements:

Brazed retention pin across the last element at downstream end of housing

End Connectors:

Plain ends

Max. operating temp.:

80°C

Design Pressure:

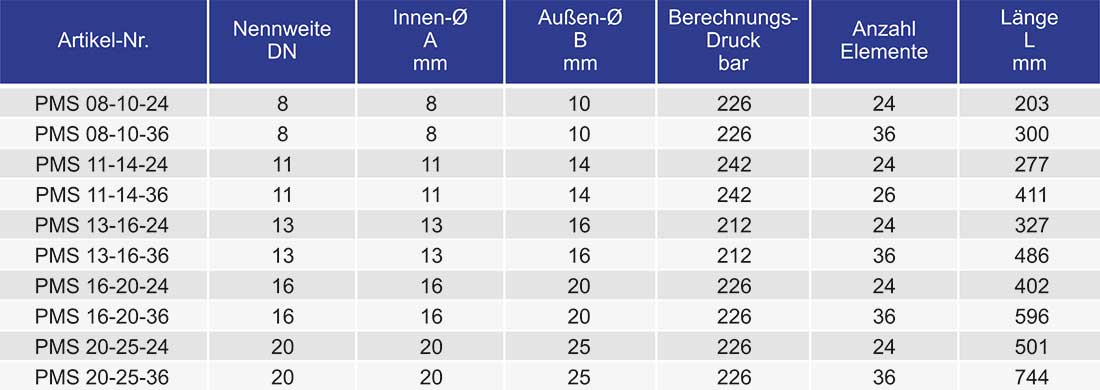

Max. allowable operating pressure (see table below) according to DIN 2413, scope of application I, permanent elongation limit 1% at 20°C, safety factor 1.7

Tolerances:

O.D. and wall: According to DIN 2391, page 1; Length +/- 1mm.

STATICS IN-LINE MIXER stainless steel/synthetics unities of the class PMS-3 have been developed as a cost-effective alternative in terms of mixing two-component synthetic resin systems. The mixing unities inside the stainless steel mixer body are made of high grade and dissolver resistant synthetics and reinforced by a cross bar arranged on the output side.

In case if high mixing proportions and/or components with extreme differences in viscosity we recommend the use if mixers with 36 elements. Concerning easy to mix media or truck agitator based functions we recommend mixers with 24 elements. Mixers made of synthetics/stainless steel are not suitable for the treatment of media with extremely high viscosity or under temperatures above 80 °C. When using mixers of class PMS-1 by means of synthetics/stainless steel unities it might be necessary to use the nominal width next in size when encountering critical pressure, decrease in pressure, i.e. especially when observing a very high grade of viscosity.

Should there be a complete precipitation hardening of the elements inside the mixer the economically priced acquisition costs allow a low cost replacement and in the same time a saving of non-productive cleaning costs.