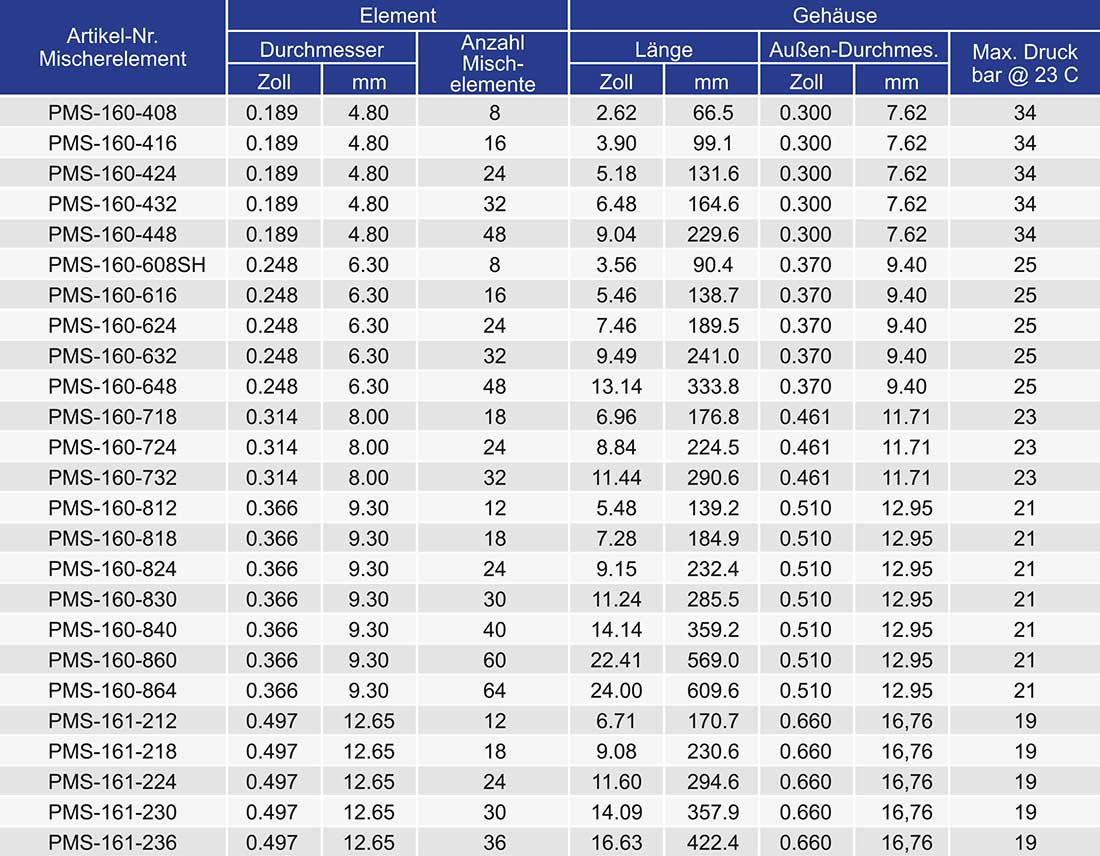

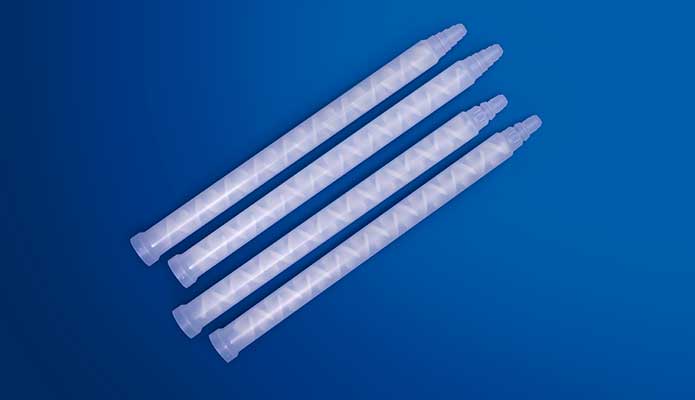

Kunststoffmischer mit Glockenanschluss

The mixers of the Series 160 offer significant advantages in terms of mixing and metering processes. The nozzles have a generally oversized bell inlet. The valves and distributors carry the A and B materials separately into the mixer.

A metal sleeve is recommended if the operating pressure in the mixer exceeds 10 bar (150 psi). All nozzles have a bellmouthed adaptor. The mixing elements are interchangeable and have different diameters. For a higher flow rate (cubic foot per second) mixer with larger diameters are recommended.

Alternatives to PMS Series 160

STATICAL MIXER header mixer of the series PMS 160 K ensure cost-effective solutions for two-component mixing operations where mixing is required immediately prior to the drag-out. In addition, these mixers can perfectly be used for post-mixing tasks used in conventional facilities.

Mixers of this model range follow solvent-free and environment-friendly requirements thanks to their cost-effectiveness. They have been developed as cost-efficient non-returnable mixers and avoid non-productive cleaning operations as well as cost-intensive solvents and their proper disposal.

Header mixers have to be installed to metering and mixing guns or to dosing systems/batchers subsequently to the back pressure valves. In order to guarantee a separate conduct of both components there is a separating plate reaching immediately right before the first mixer element. The fixing of the mixer is effected by a high-strength plastics union nut. For safety reasons the mixer shall be covered with a protective metal shell in case of higher pressure and temperatures above 40° C. The needle of the mixer is multi-graded facilitating a specific abscission in order to enlarge the outlet port diameter.